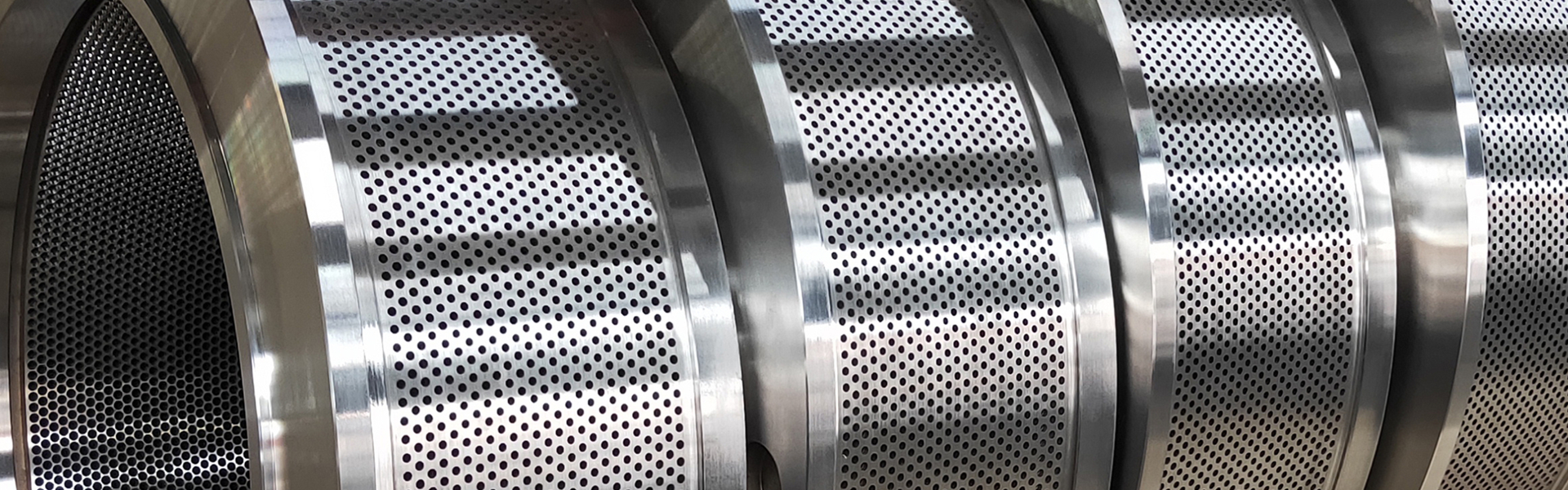

1. Pellet Die Introduction

1.1 Material of the pellet die: X46Cr13 /4Cr13(stainless steel), 20MnCr5/20CrMnTi (alloy steel) or customized

1.2 Hardness of ring die: 52-60 HRC

1.3 Diameter of pellet die can do: 1.0mm up to 28mm

1.4 Pellet die type: Ring Die, Flat Die

1.5 Compressing ratio of ring die: 1:4-1:30, as per needs.

2. Pellet Die Compressing Ratio Reference

Buyers can customize pellet die according to their own situation and requirement.

Here below is the compresssing ratio & hole diamter for reference only:

Poultry & livestock feed pellet ring die: Hole diameter 2.5-4.5mm Compression ratio 1:4.5-1:13

Fish & shrimp feed pellet ring die: Hole diameter 1.0-2.5mm Compression ratio 1:16-1:28

Biomass & wood pellet ring die: Hole diameter 6.0-12.0mm Compression ratio 1:4-1:8

3.Pellet Die Supply Scope

We can produce any type pellet die for different brands pellet mill which including but not limited to:

Muyang (Famsun), Andritz, CPM, Buhler, CPP, OGM, Zhengchang(ZCME), Kahl, Yulong(XGJ), AWILA, PTN, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promil...etc.

For Buhler pellet mill: Buhler350, Buhler400, Buhler420, Buhler AHHC520/178, Buhler AHHC530/192, Buhler660, etc.

4.Tips

How to maintain and inspect the pellet die?

1.The rollers should be correctly adjusted, make sure the hole inlets are not damaged by contact with the rollers or as a result of tramp metal;

2.Material should be evenly distributed across the whole working area;

3.Make sure that all holes work uniformly, opening the clogged holes if necessary;

4.When changing dies, carefully inspect the condition of the die seating surfaces and fixing systems including collar, clamp or wear ring.